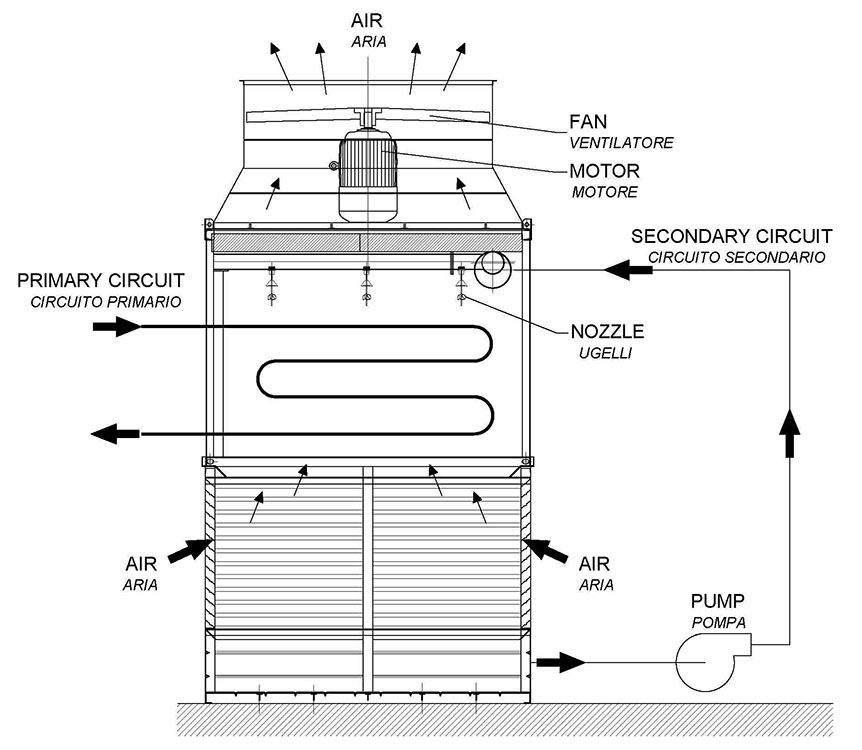

CCT Closed Circuit Cooling Tower

These closed circuit towers, also conceived in the “package”

version, is characterised by a system that excludes direct

contact among fluids, unlike open circuit towers. For both

refrigerators and condensers, heat is transmitted through a

bundle of hoses where the liquid to be cooled or the gas to be

condensed (primary circuit) circulate.

CCT Closed Circuit Cooling Tower

These closed circuit towers, also conceived in the “package”

version, is characterised by a system that excludes direct

contact among fluids, unlike open circuit towers. For both

refrigerators and condensers, heat is transmitted through a

bundle of hoses where the liquid to be cooled or the gas to be

condensed (primary circuit) circulate. On the outside, the spray

water taken from the collecting basin circulates by means of

a dedicated pump assembled and connected on board the

machine.

Building features:

• Differentiated metallic treatment according to the areas: for

external surfaces, polymerised plastic anti-corrosion cycle,

performed in the furnace, while for internal surfaces (more

exposed to corrosion) the treatment consists in three layers

of VTR directly modelled on the surfaces that have been

previously sanded.

• Ventilation groups comply with the quality and reliability of

the SCAM T.P.E. standard with resin or light alloy fans and

electric engines that are wired in a dedicated box.

• Pipes are available in hot-dip galvanised steel or in

AISI 304/316. Maximum standard pressure ranges from

1.6 to 3.0 Mpa with indicative pressure drop of 0.006 Mpa.

• The pumps of the secondary circuit are of the “flange flange”

type with “close-coupled” processing. Their geometry allows

optimal installation.

• You can request: SCAM/RS deicing resistances with SCAM/V

reintegration value and level control systems through

SCAM/LV420 sensors installed on the collecting basins.

• Doors for inspection, quality bolts, protection grids for the

ventilation groups complete this series of towers.